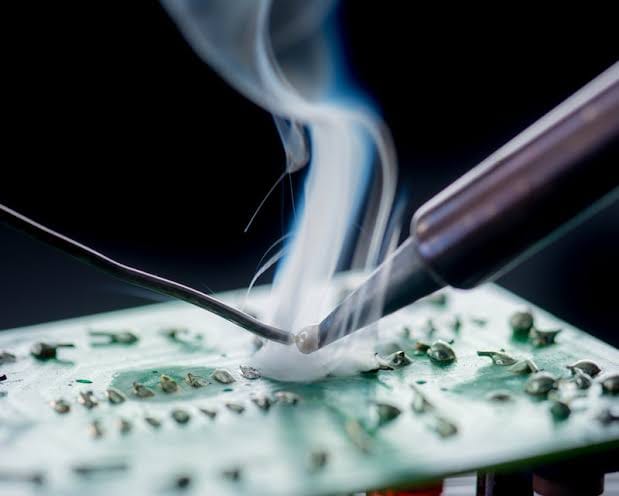

Optimal Tin-Lead Ratio for Electric Soldering - A Comprehensive Guide

Understanding the Importance of Tin-Lead Ratio in Electric Soldering

The tin-lead ratio is a critical factor in electric soldering, as it significantly impacts the performance and reliability of the solder joint. In this section, we will delve into the importance of tin-lead ratio and its effects on the soldering process.

Impact on Melting Point

The tin-lead ratio directly affects the melting point of the solder alloy. A higher tin content results in a lower melting point, while a higher lead content increases the melting point. A suitable tin-lead ratio ensures a melting point that is neither too high nor too low, allowing for efficient and effective soldering.

Effects on Strength and Conductivity

The tin-lead ratio also influences the strength and conductivity of the solder joint. A balanced ratio ensures optimal strength, while an imbalance can lead to weak or brittle joints. Additionally, the conductivity of the solder joint is affected by the tin-lead ratio, with a suitable ratio ensuring reliable electrical connections.

Ensuring a Smooth and Reliable Soldering Experience

A suitable tin-lead ratio is crucial for a smooth and reliable soldering experience. It ensures that the solder flows easily, forms a strong bond, and provides reliable electrical connections. An optimal tin-lead ratio helps prevent common soldering issues, such as weak joints, corrosion, and electrical failures.

Popular Tin-Lead Ratios for Electric Soldering

When it comes to electric soldering, the tin-lead ratio is crucial for achieving optimal results. Here, we'll explore two popular ratios, their characteristics, and applications.

63/37: A Widely Used Ratio for Electronics

The 63/37 tin-lead ratio is a widely accepted standard in the electronics industry. This ratio offers a perfect blend of properties, making it ideal for smooth and reliable soldering. The benefits of this ratio include:

- Low melting point (183°C/361°F)

- High wetting ability for easy solder spread

- Strong mechanical strength for durable joints

- Good electrical conductivity for reliable connections

60/40: A General-Purpose Ratio with Strong Electrical Conductivity

The 60/40 tin-lead ratio is a general-purpose soldering alloy with a low melting point (190°C/374°F) and strong electrical conductivity. This ratio is suitable for:

- General electronics assembly

- Repairs and maintenance

- Applications where high electrical conductivity is crucial

While these ratios are popular, it's essential to note that the optimal tin-lead ratio may vary depending on specific applications, component types, and desired properties.

Benefits of 63/37 Tin-Lead Ratio

Optimal Temperature Control

The 63/37 tin-lead ratio offers a lower melting point, making it ideal for delicate temperature requirements. This unique characteristic allows for precise control over the soldering process, reducing the risk of damage to sensitive components.

Enhanced Component Protection

Applications where parts are sensitive to high temperatures greatly benefit from the 63/37 tin-lead ratio. The lower melting point ensures that components are not exposed to excessive heat, thereby protecting them from potential damage or degradation.

Benefits of 60/40 Tin-Lead Ratio The 60/40 tin-lead ratio is widely regarded as the optimal composition for electric soldering, offering numerous benefits that make it an ideal choice for various applications. Advantages for Complex Projects

Suitable for Large Projects and Multiple Connections

The 60/40 tin-lead ratio excels in complex projects involving multiple connections and large-scale soldering. Its optimal wetting properties ensure reliable bonds between components, reducing the risk of faulty connections and electrical failures.

Enhanced Reliability and Durability

The balanced composition provides superior mechanical strength, minimizing the likelihood of solder joint fatigue and cracking. This results in more durable and long-lasting connections.

User-Friendly and Versatile

Easy to Use, Allowing New DIYers to Achieve Professional Results

The 60/40 tin-lead ratio is remarkably easy to work with, making it an excellent choice for beginners. Its forgiving nature allows DIY enthusiasts to achieve professional-grade solder joints with minimal practice.

Compatibility with Various Materials

This ratio is compatible with a wide range of materials, including copper, brass, and steel. Its versatility ensures seamless integration with diverse project requirements.

Additional Benefits

Optimal Melting Point and Flow

The 60/40 tin-lead ratio boasts a relatively low melting point (183°C/361°F), allowing for smooth and efficient soldering. Its excellent flow characteristics facilitate effortless filling of gaps and ensure strong bonds.

Cost-Effective and Widely Available

This popular solder composition is widely available and affordable, making it an economical choice for projects of all sizes.

Choosing the Right Tin-Lead Ratio for Your Project

Selecting the optimal tin-lead ratio for electric soldering is crucial to ensure reliable and high-quality connections. The ideal ratio depends on various factors, including the specific requirements of your project. In this section, we will delve into the key considerations for choosing the right tin-lead ratio.

Understanding Your Project's Requirements

Before selecting a tin-lead ratio, it's essential to consider the specific needs of your project. Some key factors to keep in mind include:

- Temperature sensitivity: If your project involves exposure to high or low temperatures, you'll need a ratio that can withstand these conditions.

- Conductivity needs: The tin-lead ratio affects the solder's electrical conductivity. Choose a ratio that meets your project's conductivity requirements.

Balancing Melting Point, Strength, and Conductivity

The ideal tin-lead ratio balances three critical factors:

- Melting point: A lower melting point makes soldering easier, but may compromise strength and durability.

- Strength: A higher lead content increases strength, but may raise the melting point and reduce conductivity.

- Conductivity: A higher tin content enhances conductivity, but may lower the melting point and strength.

By considering these factors and selecting a ratio that balances them, you'll achieve optimal results for your project.

Comments ()